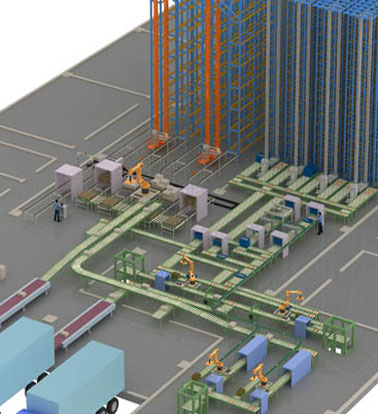

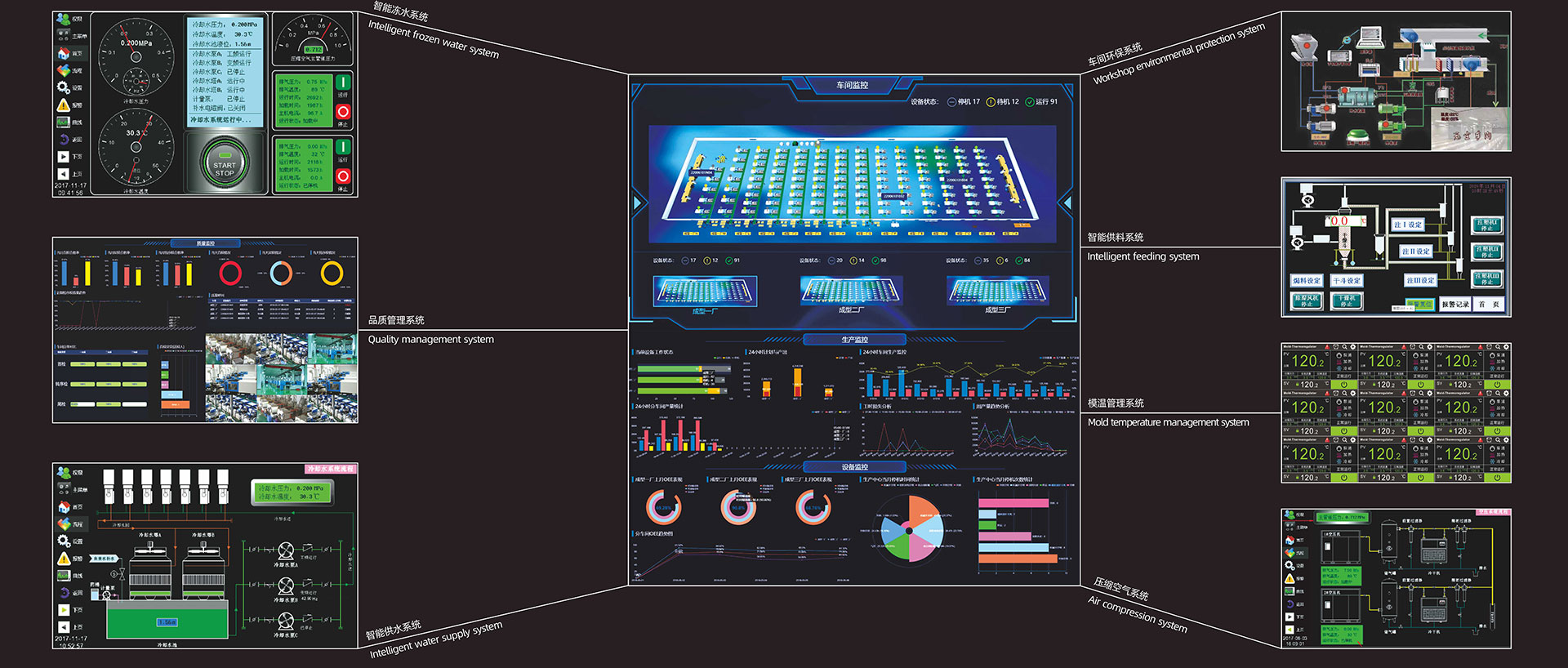

SOXI Intelligent Equipment Co., Ltd. was established in 2017. A plastic machinery factory focusing on the R&D, production, and sales of injection molding peripheral equipment. The main production equipment includes Central Loading System high-gloss mold temperature control, water temperature control, and three-in-one dehumidification Equipment products such as dryers, masterbatch machines, crushers, chillers, etc.

Remarks: Soxi Headquarters: Shenzhen SOXI Machinery Equipment Co., Ltd. No. 122, Fumin Xianwu Industrial Zone, Guanlan Town, Longhua District, Shenzhen, established in 2004.

English

English